Solutions

Save the Planet by Getting Our Solutions

- Satisfaction Value For Money Solution

- Simple, reliable, low cost

- Unique configuration avoids many problems

- Suitable for a wide range of variable feedstocks

Electricity

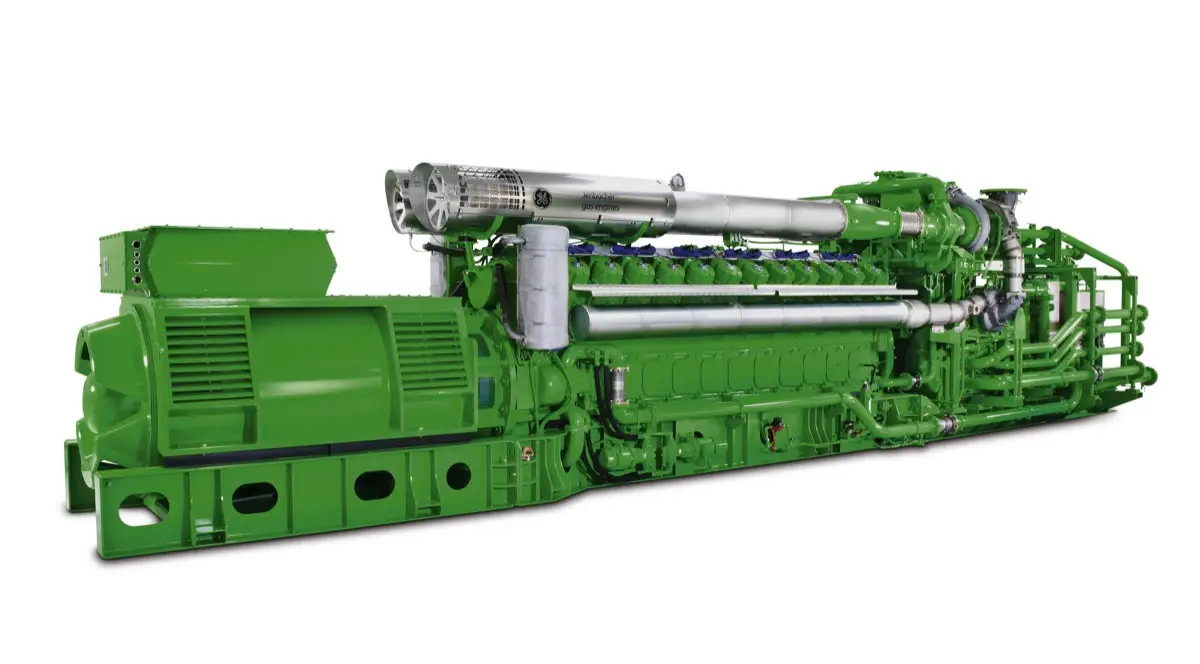

In MIHG energy from waste plants, electricity can be produced from clean syngas in a high efficiency gas engine. Importantly, the thermal efficiency can meet EU R1 energy efficiency requirements which is very difficult to achieve at small scale using incineration technology.

Electricity can be used on site or exported to the grid and typically attracts green credits for the renewable portion of the waste.

Co-generation

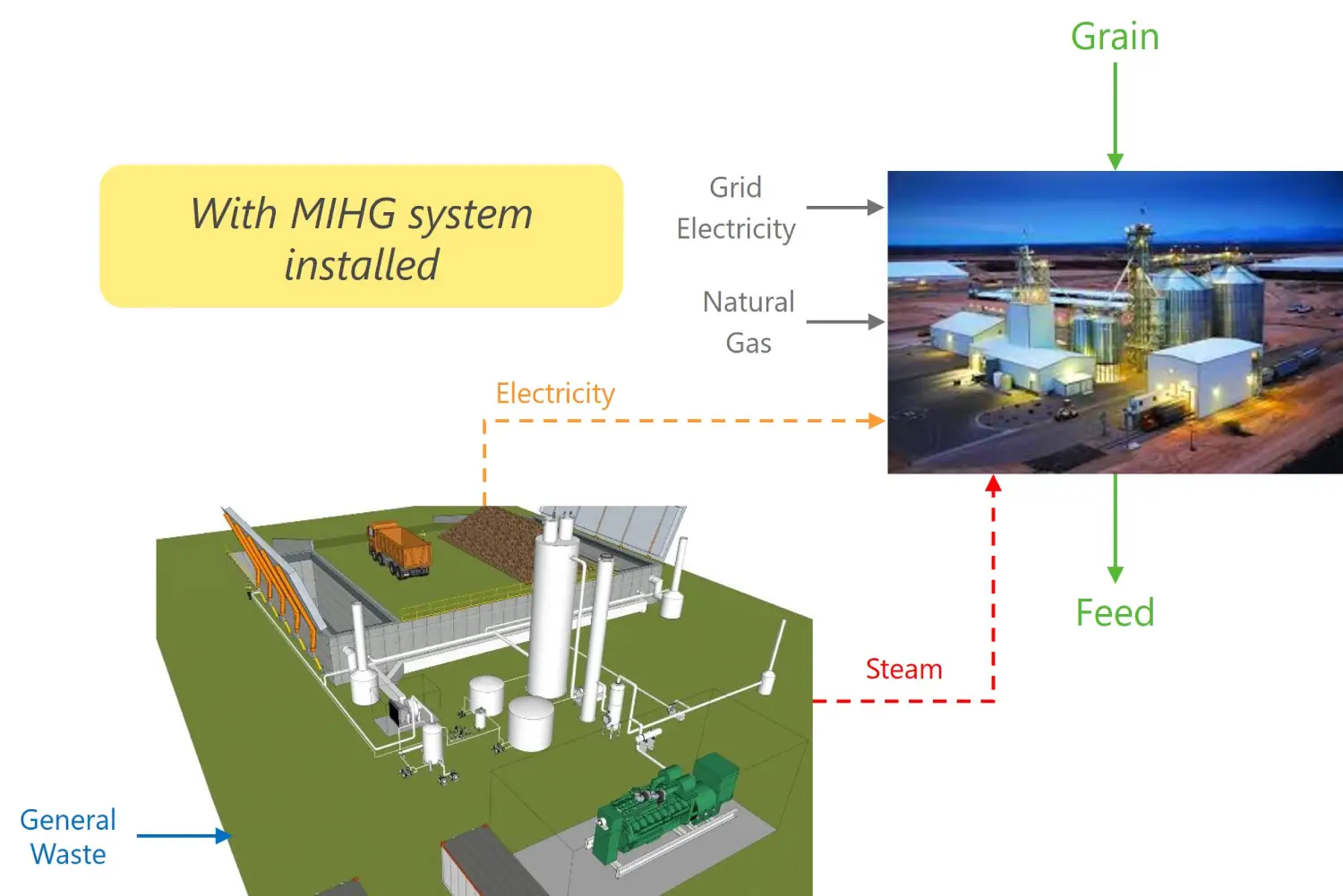

Co-generation refers to the production of multiple products, in particular to the simultaneous production of electricity and steam or hot water. Co-generation applications have high thermal efficiency and superior economic returns as all of the energy generated from the waste is utilised efficiently.

Applications of co-generation using the MIHG technology exist across a range of industrial processes, especially where significant amounts of electricity are being consumed together with natural gas or LPG for heat production. Examples include general manufacturing, feed mills, small scale industrial furnaces and the like.

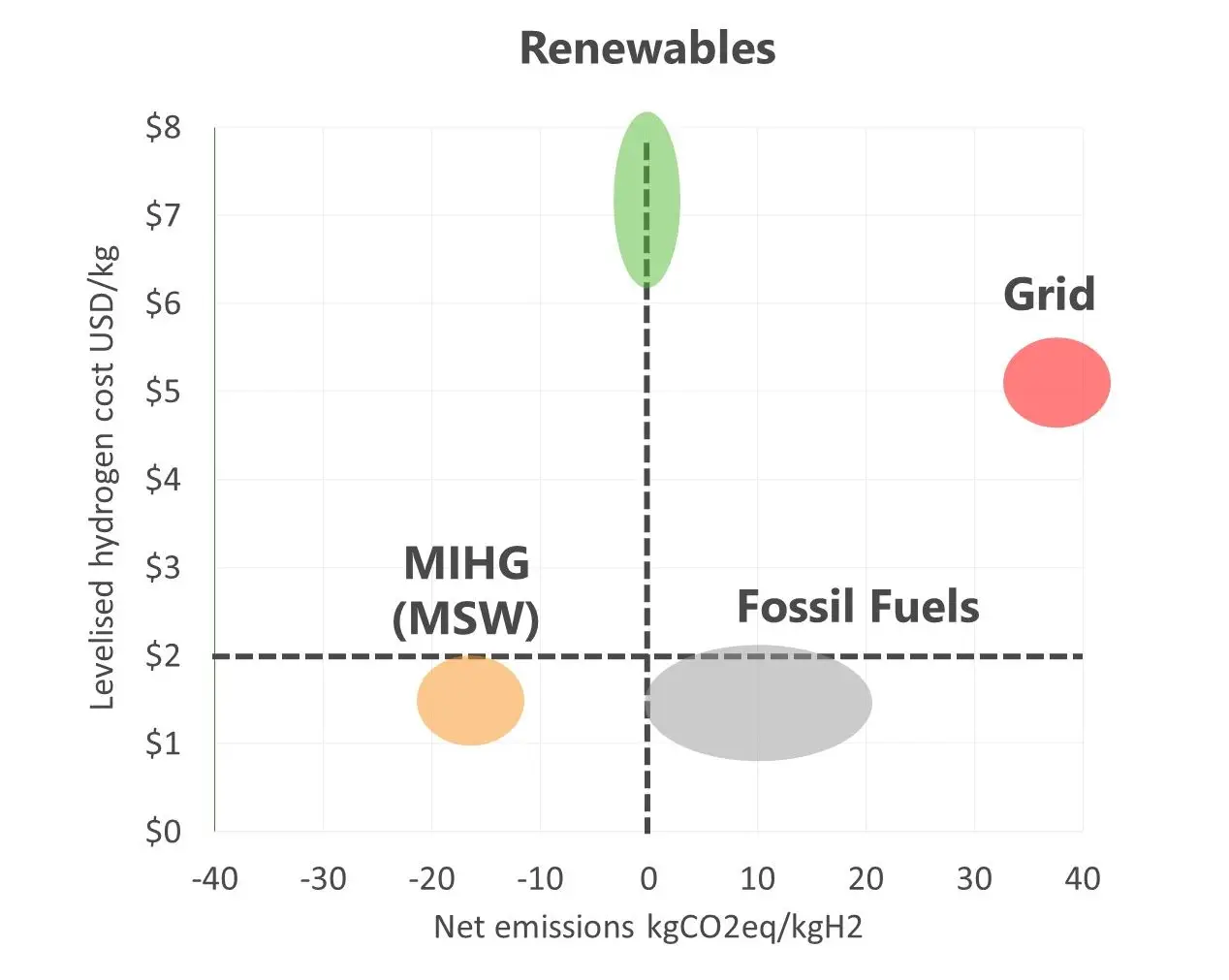

Hydrogen

Hydrogen is a clean energy carrier which has been identified as an important solution to reduce our GHG emissions. At point of use hydrogen emits no GHG emissions and can be used in a wide range of applications, including:

- Fuel cell vehicles for mobility

- Energy storage to balance intermittent renewables

- Producing renewable chemicals, such ammonia and methanol

- Industries such as steel making

- Co-injection in the pipeline network to decarbonise natural gas

Biofuels and Chemicals

The MIHG process produces syngas which contains CO and H2 that can be converted to biofuels and chemicals using proven methods including:

- Fischer Tropsch process to produce diesel and jet fuel

- Catalytic synthesis to produce methanol

- Biological gas fermentation to produce ethanol and other chemicals

Production of biofuels and chemicals may be favoured for larger projects or where local subsidies exist for renewable fuels.

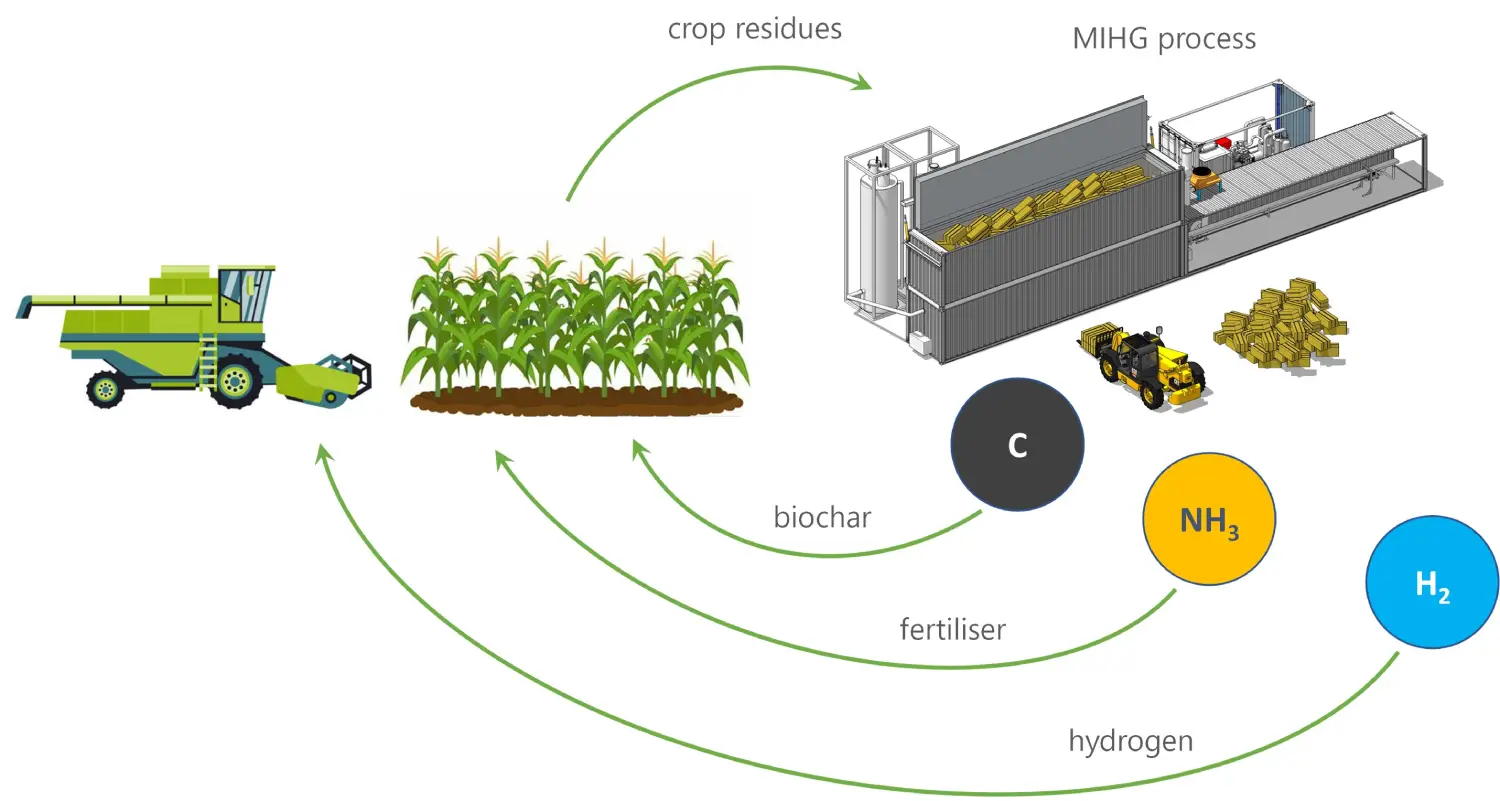

Ammonia

Wildfire Energy is working with Grains Research Development Corporation and CSIRO in Australia to engineer a solution which will convert crop residues into hydrogen, ammonia and biochar on the farm. The hydrogen would be used to power machinery, while ammonia is used as a fertilizer and biochar is returned to the soil to sequester carbon. The integrated scheme is carbon negative and reduces farm input costs leading to a more circular economy on the farm.

We are working with Grains Research Development Corporation and CSIRO in Australia to engineer a solution which will convert crop residues into hydrogen, ammonia and biochar on the farm. The hydrogen would be used to power machinery, while ammonia is used as a fertilizer and biochar is returned to the soil to sequester carbon. The integrated scheme is carbon negative and reduces farm input costs leading to a more circular economy on the farm.

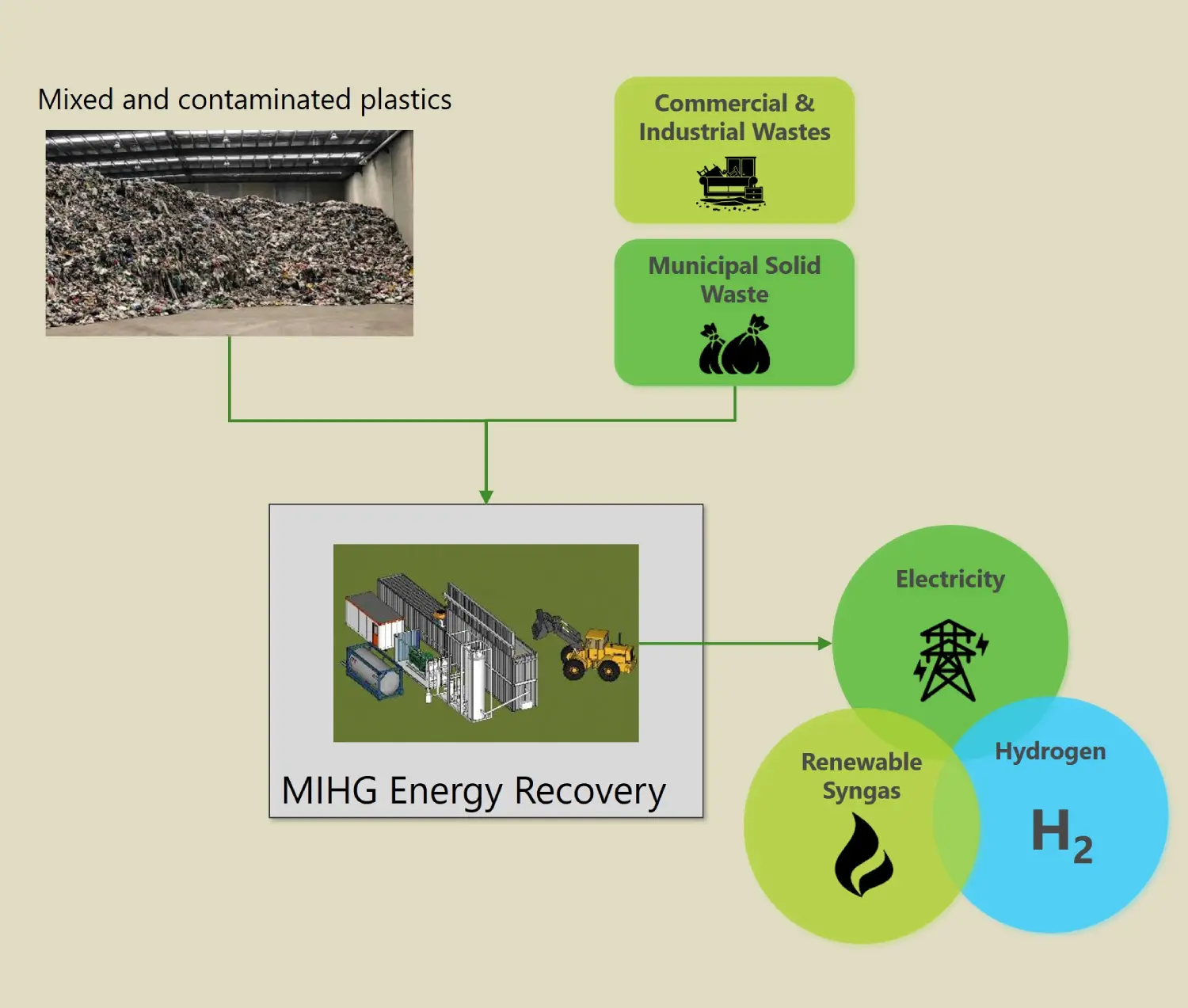

Mixed Plastics

Globally mixed and contaminated plastics are a major disposal problem and environmental issues. Many material recovery facilities (MRFs) produce plastics with high levels of contaminants, such as glass fines, rendering them unrecyclable. In Australia only 12% of plastics are recycled.

Wildfire Energy’s MIHG technology can be applied to recover energy from mixed plastics residuals that can’t be recycled and are destined for landfill.

- Globally mixed and contaminated plastics are a major disposal problem and environmental issues. Many material recovery facilities (MRFs) produce plastics with high levels of contaminants, such as glass fines, rendering them unrecyclable. In New Zealand only 16% of plastics are recycled.

- MIHG technology can be applied to recover energy from mixed plastics residuals that can’t be recycled and are destined for landfill.

Circular Economy

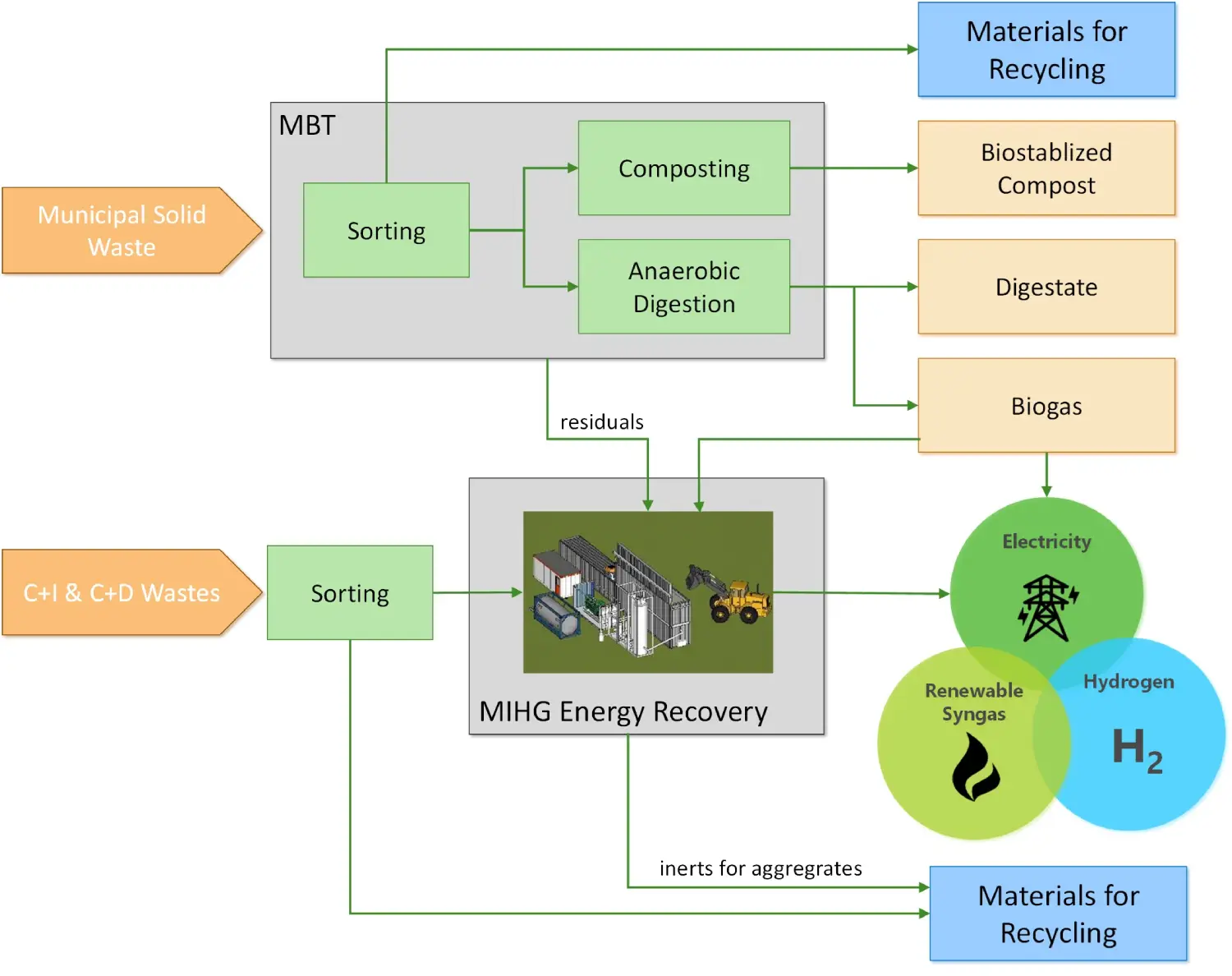

MIHG energy from waste plants can help support the circular economy.

- Metropolitan councils wish to increase recycling and reuse of wastes by building Material Recovery Facilities (MRFs) and Mechanical Biological Treatment (MBT) facilities

- However, in most cases, residual wastes are still being sent to landfill

The illustration below shows how a MIHG energy from waste plant can be integrated with waste management infrastructure to maximise the recycling of the domestic and industrial wastes, composting of organic wastes and production of renewable energy from biogas and from residual wastes.

Ready to power a cleaner future?